Replacing the Internal Drive in the 788T

The internal drive of the 788T and 788T-SSD can be removed and replaced if the drive is damaged, a different capacity drive is required, or if upgrading to a Solid State Drive (SSD). In typical service conditions Sound Devices recommends hard drive replacement once every three years.

The information below provides important information for choosing the correct substitute drive, an explanation of drive failures, and step-by-step instructions on how to replace the internal drive of the 788T Recorder.

Choosing a Replacement Hard Drive

The 788T ships with a 2.5-inch, 5400 RPM hard drive with a SATA interface. Sound Devices has chosen the specific mechanism for vibration and shock resistance. Most 2.5 inch drives conforming to the SATA specification can be substituted for the factory hard drive. When choosing a substitute hard drive, note that higher RPM hard drives draw more current, reducing battery run time. Higher speed drives may be used with the 788T, however, they will only marginally improved data transfer times. They have no impact on the robustness or reliability of recording, while increasing power consumption.

The 788T-SSD ships with an upgraded 2.5-inch Solid State Drive (SSD) with a SATA interface. Upgrading to an SSD further enhances the performance and reliability of the recorder. SSD mechanisms allow for faster transfer speeds, zero acoustical noise output, and maximum vibration and shock resistance.

The 788T/788T-SSD can address drives with capacities up to 2 TB. The drive installed in the 7-Series is formatted at the factory as a single-partition FAT32 volume. If a drive with multiple partitions is installed, the 788T will only “see” and address the primary partition.

Drive Failures

Hard disk drives are mechanical devices and are susceptible to damage from physical shock. One type of physical shock, called operating shock, occurs when the drive head is over the drive platters reading or writing data. When physical shock to the drive occurs during operation, it is possible for the head and the platters to come into contact, causing both components to be damaged. The second type of shock, called non-operating shock, occurs when the head is in the unloaded position, or not positioned over the platters. When a physical shock occurs in the non-operating state, the head can contact the ramp it is positioned over and damage the ability of the head to read and write data to the hard disk drive. All devices with hard drives are subject to damage from operating and non-operating shock.

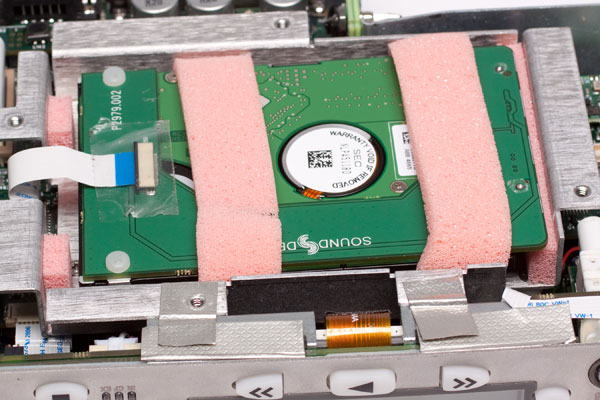

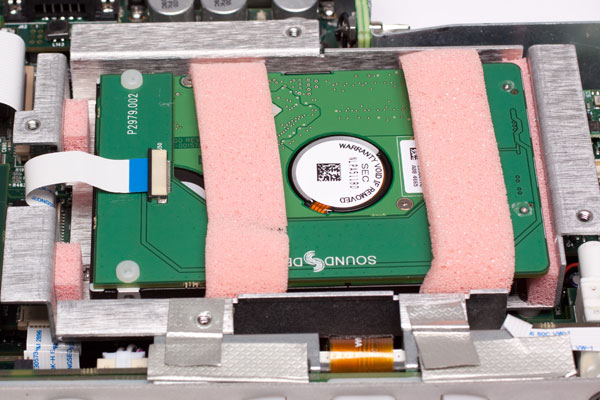

The mechanical construction of the 788T is designed to minimize the transmission of shock to the hard drive. The drive is isolated from the chassis using special shock-reducing closed-cell foam. This material increases the amount of shock the hard drive can withstand. Additional protection can be achieved by operating the unit in a carry case.

There is additional risk to a hard drive from sudden temperature changes, which can create condensation inside the drive. This condensation can lead to the drive’s read/write heads adhering to the disk surfaces which will, in turn, stop the hard disk from rotating. Condensation tends to occur when the temperature inside the drive suddenly falls, for example, just after the unit is moved to a new location, or after operation is stopped in a cold environment. Sudden changes in temperature or air pressure can also cause disk surface materials to evaporate, which can also cause the head to adhere to the disk surface. This can happen when a hard disk drive is left unused for a long period of time.

If the recorder is regularly used in applications subject to extreme motion or altitudes greater than 10,000 feet, Sound Devices recommends either upgrading the internal drive to an SSD or recording to CompactFlash cards only.

Replacing the Internal Hard Drive

While the internal drive in a 788T is replaceable, it is not intended to be a swappable, deliverable medium. Its multi-pin connector is not rated for repeated insertion and removal cycles and may be prone to breakage with repeated cycling.

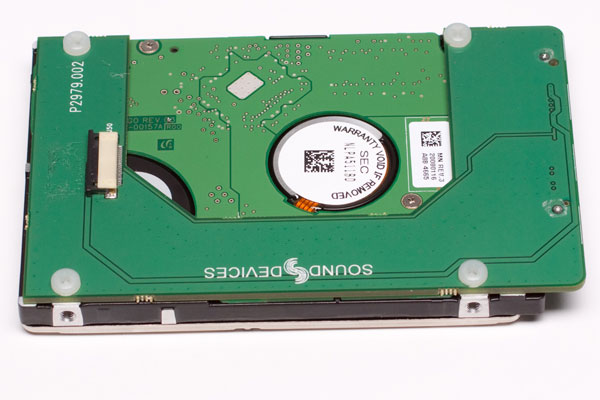

The drive is mounted to the bottom-side of the recorder’s chassis and is screwdriver accessible. The drive is “suspended” in the unit with shock absorbing material and is attached to the main circuit board by a “flex board”. Since the unit’s high-density circuitry and tight construction require specific electronics knowledge, Sound Devices strongly recommends drive replacement be performed by a knowledgeable technician using proper ESD precautions. Drive replacement done by a knowledgeable technician has no warranty implications.

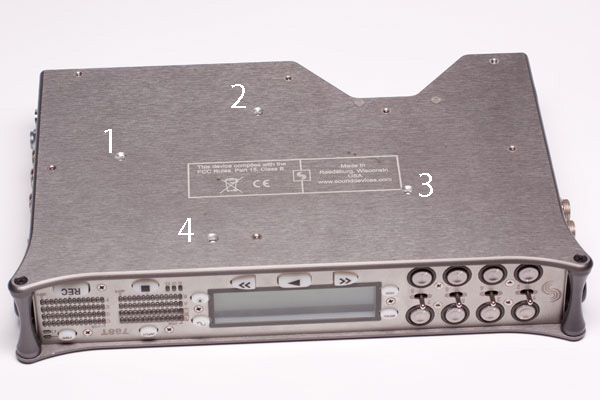

First, place the recorder on a steady flat, non-slip surface so that the top panel is exposed. All powering sources should be disconnected at this time. Using a #1 Phillips head screwdriver remove the nine Black Oxide Phillips head screws.

Second, carefully flip the recorder over, taking care to keep the top panel in place since it is no longer securely attached to the 788T. Using a #1 Phillips head screwdriver remove the four screws located in the center of the bottom panel.

Remove the bottom panel using your hands. Do NOT use tools to pry the bottom panel off since may compromise the integrity of the EMI and RF gaskets.

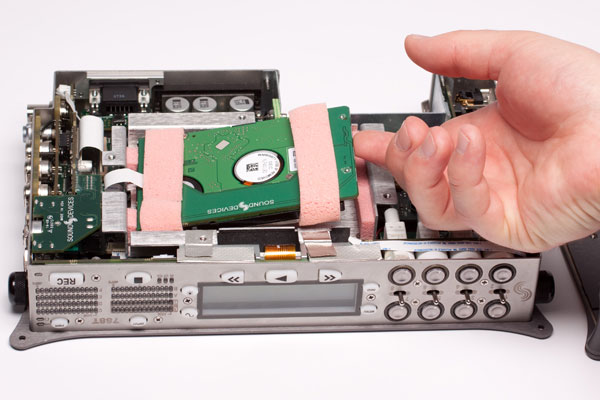

Slightly lift the drive assembly out of the drive plate. Take care not to lift too high as the ribbon connector is still attached.

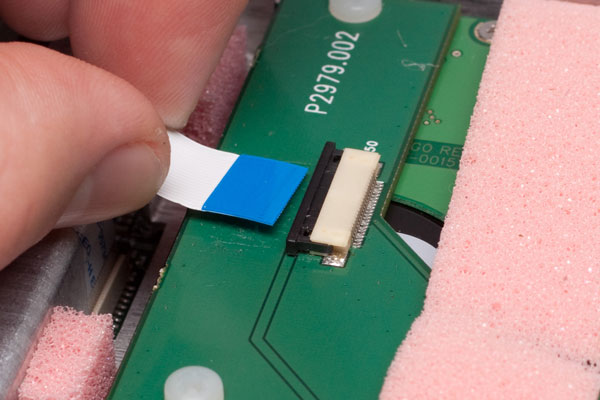

Next, gently slide the pink protective foam ring closest to the ribbon connector down to expose the two white nylon screws and the ribbon mating connector.

Return the drive assembly to it's original position in the drive plate.

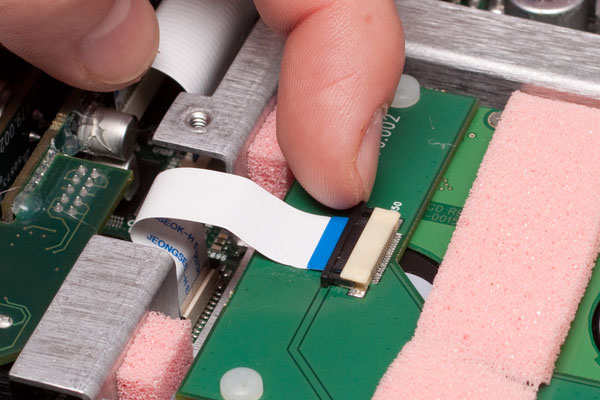

Some units will have a piece of adhesive tape covering the ribbon and mating connector, others may use double-sided adhesive to stick the ribbon to the circuit board. Remove the adhesive tape to detach the ribbon from the circuit board assembly.

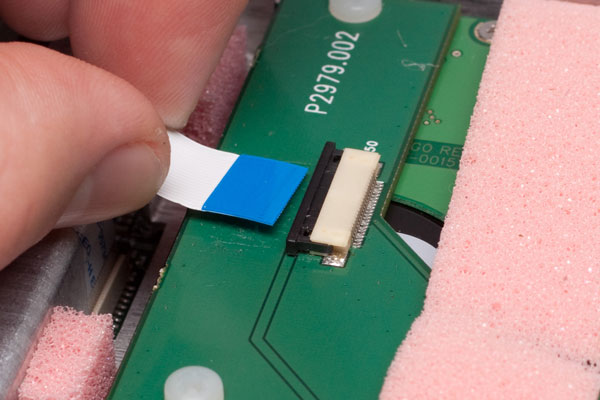

Now, unlock the ZIF mating connector with your fingernails by sliding the black locking mechanism towards the ribbon. Do not use sharp tools to separate this connection. Clip your fingernails before taking photos :)

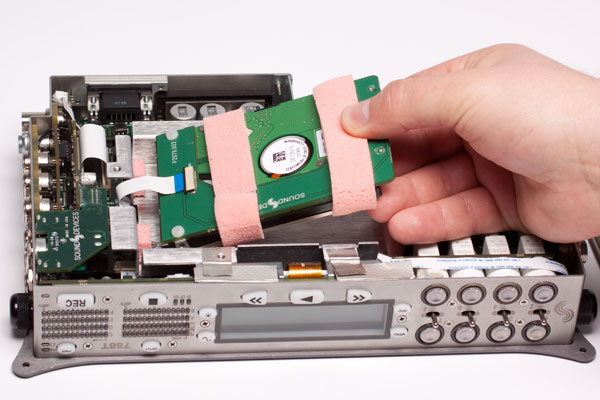

Carefully disconnect the ribbon head mating connector from the drive assembly circuit board.

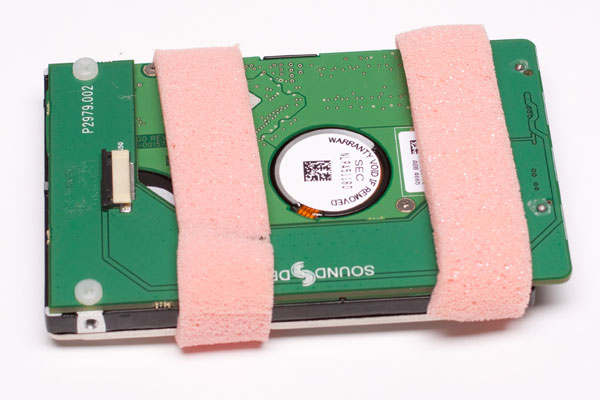

Remove the drive assembly and place it on a steady, flat, non-slip surface with the mating connector side up.

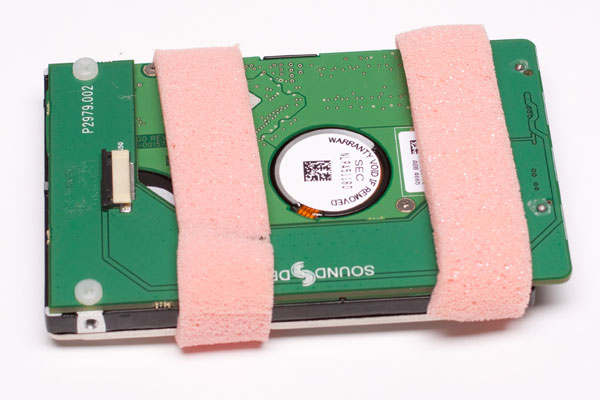

Remove both of the pink protective foam rings carefully - you'll need them later.

Using a #1 Phillips head screwdriver remove the four white nylon screws securing the drive to the drive assembly circuit board.

Flip the drive assembly over exposing the internal drive.

Disconnect the drive from the drive assembly circuit board's SATA connector.

Next, connect the new SATA drive to the drive assembly circuit board's SATA connector.

Then, flip the drive over once again to expose the drive assembly circuit board. Attach the four white nylon screws to secure the new drive to the drive assembly circuit board. Take care not to over tighten.

Slide the pink protective foam ring over the drive assembly leaving the ribbon connector exposed. Slide the other pink protective foam over the mounting screws.

Reconnect the ribbon connector to the 788T drive assembly header connector.

Secure the ribbon connector by sliding the black locking mechanism towards the mating connector.

Secure the ribbon to the drive assembly using the adhesive tape discussed in earlier.

Slide the pink protective foam ring over the mating connector and mounting screws then gently place the drive assembly in the 788T drive plate.

Replace the bottom panel making sure that the all around panel fits in the grooves of the bottom panel. Then, reattach the four small Black Oxide Phillips head screws to the bottom panel.

Now, flip the recorder over so that the top panel is exposed, making sure the all around panel fits in the grooves of the bottom panel. Finally, reattach the nine Black Oxide Phillips head screws to the top panel.